-

instruments de essai de pétrole

-

Instruments d'essai d'antigel d'huile de graissage et de graisse

-

Équipement d'essai de gazole

-

Équipement d'essai d'huile de transformateur

-

Instrument d'essai d'alimentation

-

Instruments pharmaceutiques d'essai

-

Équipement d'essai d'huile de table

-

Instruments d'analyse chimique

-

Équipement d'essai d'huile lubrifiante

-

Instrument d'essai de farine

-

Instruments d'essai de nourriture

-

Équipement d'essai de pétrole brut

-

Équipement d'essai d'huile hydraulique

-

Appareil de contrôle de point d'inflammabilité

-

Appareil de contrôle cinématique de viscosité

-

Appareil de contrôle de point de congélation

-

Appareillage de pénétration de cône

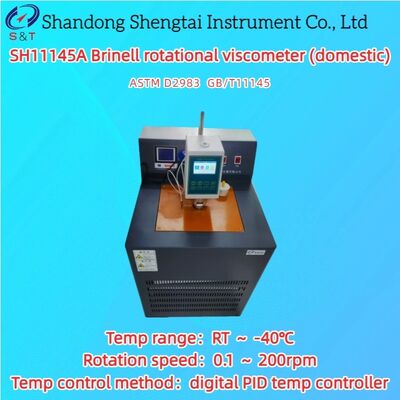

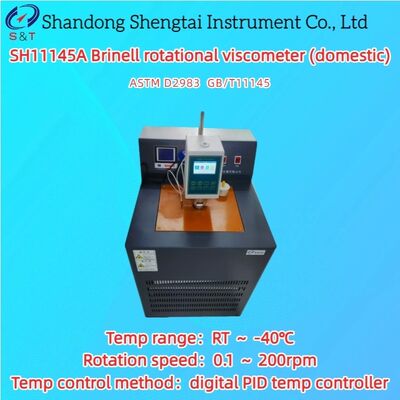

Brinell Rotational Viscometer RT ~ -40℃ Viscosity Range 1-6 Million Mpa.S ASTM D2983

| Lieu d'origine | Chine |

|---|---|

| Nom de marque | Shandong Shengtai Instrument Co.,Ltd |

| Certification | ASTM D2983 GB/T11145 |

| Numéro de modèle | SH11145A |

| Quantité de commande min | 1 |

| Détails d'emballage | caisse en bois |

| Délai de livraison | 7 à 15 jours ouvrables |

| Conditions de paiement | T/T |

| Capacité d'approvisionnement | 10000 ensembles/an |

Contactez-moi pour des aperçus gratuits et des bons.

WhatsApp:0086 18588475571

wechat: 0086 18588475571

Skype: sales10@aixton.com

Si vous avez n'importe quel souci, nous fournissons l'aide en ligne de 24 heures.

x| Plage de température | TA ~ -40℃ | Méthode de contrôle de la température | contrôleur de température numérique PID |

|---|---|---|---|

| Vitesse de rotation | 0.1 ¢ 200 tours par minute | configuration du rotor | 1 à 4 rotors (standard) 0 rotor (en option) |

| Interface de données | RS232 | Fonction d'impression | mini imprimante |

| Mettre en évidence | Brinell rotational viscometer for lube oil,Rotational viscometer with -40℃ range,ASTM D2983 viscosity testing equipment |

||

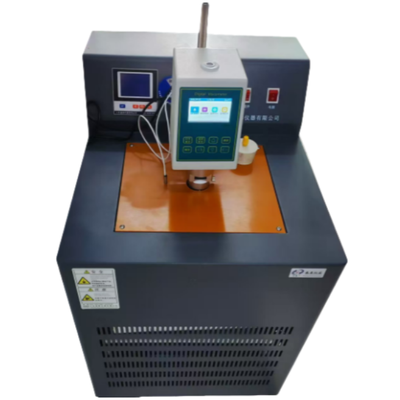

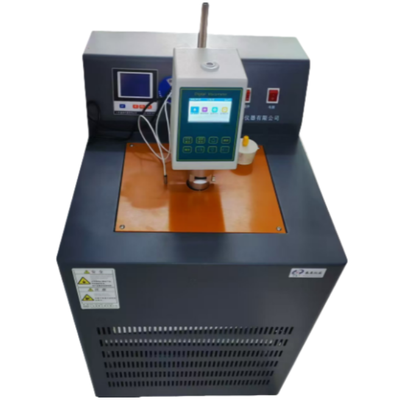

SH11145A Brinell rotational viscometer domestic

The SH11145A Low Temperature Brinell Viscometer for Lubricating Oil is designed and manufactured strictly in accordance with GB/T11145-2014 Determination of Low Temperature Viscosity of Lubricants using the Brockfield Viscometer Method. It is suitable for detecting automotive fluid lubricants with a viscosity range of 1 to 6000000mPa. s, such as gear oil, hydraulic transmission oil, industrial and automotive hydraulic oil. The method for determining the shear rate viscosity of automotive fluid lubricants involves placing the sample in a cold bath at the test temperature, connecting a Burgundy viscometer and a spindle, selecting the appropriate rotational speed, and maintaining a constant temperature for 2 to 16 hours before measuring the low-temperature Burgundy viscosity of the sample.

Main technical specifications, parameters, and performance characteristics:

| Applicable standard | ASTM D2983 GB/T11145 |

| Temp range | RT ~ -40℃ |

| Temp control method | digital PID temp controller |

| Rotation speed | 0.1 ~ 200rpm |

| Rotor configuration | 1-4 rotors (standard) 0 rotors (optional) |

| Viscosity range | 1-6 million Mpa. s (cp) 15mpa. s below, it is recommended to use rotor 0 # |

| Viscosity temperature curve | displayed on the touch screen |

| Measurement error | ± 1% (FS) Newtonian fluid |

| Repeatability | ± 0.2% (FS) Newtonian fluid |

| Screen display | viscosity, shear rate, shear stress, speed, temperature, percentage torque, rotor number, and the maximum measurable viscosity value of the selected rotor at the current speed, etc |

| Timing function | Touch screen displays timing function |

| Data interface | RS232 |

| Printing function | Mini printer |

| Cooling method | Compressor cooling |

![]()

Note: The appearance pictures, dimensions, volume, and weight of the instrument are for reference only. If there are any updates to the instrument, there may be slight changes without prior notice.

Shandong Shengtai Instrument Co., Ltd. provides the following quality assurance for the instruments sold to you:

----The provided instrument materials are brand new, meet national quality standards, and have a manufacturer's certificate of conformity;

----The materials and main components provided meet the technical requirements specified in the technical documentation;

----The overall quality assurance period of the equipment is one year (excluding normal wear and tear of vulnerable parts).

----We are responsible for free maintenance of any instrument quality issues that occur during the warranty period. Due to equipment malfunction caused by the user's responsibility, we are responsible for repairing and charging reasonable fees.

----Lifetime discounted supply of parts for equipment, and lifetime maintenance and repair of the entire machine.

----After the expiration of the warranty period, if the user needs maintenance and technical services, we will only charge a cost fee.

Packing list

| Number | Name | Quantity | Unit | Note |

| 1 | Host | 1 | Unit | |

| 2 | Rotors 1-4 | 1 | Set | |

| 3 | Rotor No.0 | 1 | Set | |

| 4 | Power adapter | 1 | Set | |

| 5 | Protective frame | 1 | Piece | |

| 6 | Base | 1 | Piece | |

| 7 | Lifting column | 1 | Set | |

| 8 | Temperature sensor | 1 | Piece | |

| 9 | Crossbar | 1 | Root | |

| 10 | Hex key | 1 | Piece | |

| 11 | Wrench | 1 | Piece | |

| 12 | User manual, certificate of conformity, warranty card | 1 | Set | |

| 13 | Temperature control device | 1 | Unit |